Application areas: polyurethane rigid foam, flexible foam, self-skinning, shoe materials

DY-5115

The Magic of Catalysts: Explaining How They Work

I. What is a catalyst?

A catalyst is a substance that speeds up the process of a chemical reaction, but is not involved in the chemical reaction itself. The addition of a catalyst can increase the efficiency of a chemical reaction by greatly reducing the time and temperature required for it to reach equilibrium.

Classification of catalysts

Catalysts are mainly divided into two categories: one is inorganic catalysts, such as metal catalysts, oxide catalysts, acid-base catalysts, etc.; and the other is organic catalysts, such as enzyme catalysts, biocatalysts and so on.

The working principle of catalyst

The working principle of catalyst is based on the adsorption and dissociation of reactants, as well as the intermediate formation and cleavage processes occurring on the catalyst surface. The following are the basic steps in the working principle of a catalyst:

1. adsorption: the catalyst is able to adsorb on the surface of reactant molecules, changing the charge distribution and molecular structure of the reactant molecules so that they are easy to undergo chemical reactions on the catalyst.

2. Activation: After adsorbing the reactants, the catalyst stimulates the molecules to undergo chemical reactions by providing electrons, dismantling chemical bonds, or triggering charge transfers between molecules so that the energy adsorbed by the reactants is reduced.

3. Reaction: the formation of intermediates on the surface of the catalyst and their reaction, i.e. the catalyst acts as a site for the reaction and facilitates the chemical change of the reactants into the desired product.

4. Dissociation: the resulting products leave the surface of the catalyst so that the catalyst can again adsorb new reactant molecules.

IV. Role of catalyst

As a special substance, catalyst can help reactant molecules combine and react more quickly and easily, in addition, catalyst also has the following roles:

1. reduce reaction activation energy: catalysts make it easier to combine reactant molecules into desired products by adsorption and activation of reactant molecules, and they can reduce the activation energy needed for the reaction and accelerate the reaction speed.

2. Improvement of reaction selectivity: catalysts can control the location and direction of the reaction so that a specific chemical reaction occurs without causing unnecessary side reactions.

3. Improvement of reaction efficiency: catalysts can increase the efficiency of the reaction, reduce reaction time and energy consumption, save raw materials and accelerate the preparation of products.

V. Conclusion

Catalysts play a vital role in chemical reactions. Through the process of adsorption, activation, reaction and dissociation, catalysts can accelerate the chemical reaction, improve the reaction efficiency and increase the reaction selectivity, which makes the chemical synthesis more accurate and efficient. Therefore, catalysts have become an important and indispensable part of the modern chemical industry.

Related reading:

NT CAT K-15

2-(2-Aminoethoxy)ethanol

Dabco NE1060/Non-emissive polyurethane catalyst

High efficiency amine catalyst/Dabco amine catalyst

NT CAT BDMA

NT CAT PC-8

N-Ethylmorpholine

Bismuth 2-Ethylhexanoate

High Quality BDMA / 103-83-3 / Benzyldimethylamine / N,N-dimthylbenzylamine

Toyocat ETS Foaming catalyst Tosoh

Jeffcat ZF-22

Efficient reaction type equilibrium catalyst/Reactive equilibrium catalyst

Tetrachloroethylene Perchloroethylene CAS:127-18-4

Perchloroethylene, also known as perchloroethylene, is an organic compound with the chemical formula C2Cl4 and is a colorless liquid.

Chinese name: tetrachloroethylene

Foreign name: tetrachloroethene

Alias: perchloroethylene

Chemical formula C2Cl4

Molecular weight 165.833

CAS No. 127-18-4

EINECS No. 204-825-9

Melting point-22 ℃

Boiling point 121 ℃

Water solubility

Density1.622 g/cm³

Appearance Colorless liquid

Safety Description S7; S16; S23; S24; S36/37; S45; S61

Hazard symbol Xn

Hazard description R40; R51/53

Physical and chemical properties

Density: 1.622g/cm3

Melting point: -22℃

Boiling point: 121℃

Refractive index: 1.505 (20℃)

Saturated vapor pressure: 2.11kPa (20℃)

Critical temperature: 347.1℃

Critical pressure: 9.74MPa

Appearance: colorless liquid

Solubility: insoluble in water, miscible in most organic solvents such as ethanol, ether, chloroform, etc.

Uses: Mainly used as organic solvent, dry cleaning agent.

Mainly used as organic solvent, dry cleaning agent, also can be used as solvent for adhesive, degreasing solvent for metal, desiccant, paint stripper, insect repellent, fat extractant, also can be used in organic synthesis.

Storage and transportation:

It should be sealed and stored in dry, cool and ventilated warehouse

Packing:

200KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. After the original packaging, please fasten the packaging cover as soon as possible to prevent moisture and other substances from mixing and affecting the performance of the product. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

HDI Low Viscosity AsahiKasei TUL-100

HDI Low Viscosity AsahiKasei TUL-100

ABOUT:

Product Class: Isocyanate

DURANATE TUL-100 by Asahi Kasei is hexamethylene diisocyanate (HDI) trimer with extra-low viscosity and high NCO content. Acts as a curing agent for urethanes. Exhibits excellent weatherability, good chemical & abrasion resistance, good compatibility and drying properties. Shows excellent color retention and outstanding performance. DURANATE TUL-100 is suitable for automotive, architectural, industrial, consumer electronic and information technology Possible applications could be gravure, offset and screen inks.

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : sales@newtopchem.com

HDI Low Viscosity AsahiKasei TLA-100

HDI Low Viscosity AsahiKasei TLA-100

Type:

Aliphatic polyisocyanate based on hexamethylene diisocyanate.

Features:

# High NCO content

# Low viscosity

# Excellent weather resistance

# Excellent Compatibility

# Good coating film appearance

Applications:

# Two-component applications

# Automotive OEM coatings

# Automotive refinishes

# Plastic coatings

Typical properties:

Appearance |

Colorless to slightly yellowish clear liquid |

Non-volatile |

100 wt% |

Solvent |

None |

NCO content |

23.5 wt% |

Viscosity |

500 mPa·s at 25’C |

Color value |

< 1 (Gardner) |

NCO equivalent weight |

Approx.180 |

These values provide general information and are not part of the productspecifications.

Comparison with Conventional Trimer:

TLA-100 |

Conv Trimer |

|

Viscosity mPa * s/25℃ |

500 |

2,700 |

NCO content % |

23.5 |

21.7 |

Functionality |

3.0 |

3.4 |

HDI conc. After 50℃ . 1 month |

Low |

Low |

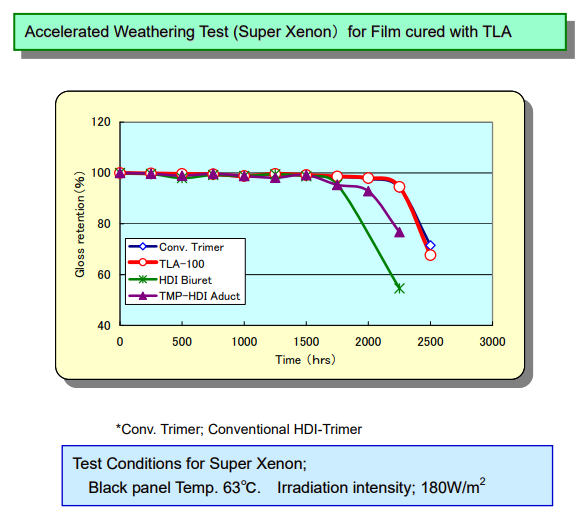

Weather resistance of cured film |

Excellent |

Excellent |

Hardness of cured film |

High |

High |

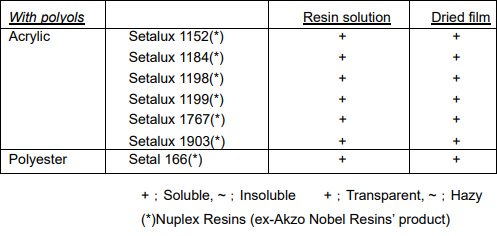

Compatibility with polyols:

Mixing ratio of DURANATETM TLA-100 with polyols is based on NCO/OH equivalentratio of 1/1 .

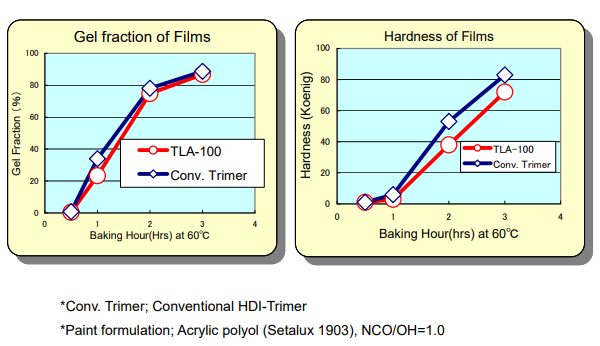

Development of gel fraction & hardness:

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : sales@newtopchem.com

HDI Waterborne Covesro XP2655

HDI Waterborne Covesro XP2655

ABOUT:

Hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).Hardener for waterborne two-component polyurethane systems.

Product Types

-

HDI

-

PIC

-

Hydrophilic polyisocyanate

-

Aliphatic polyisocyanate

-

Crosslinkers

-

Polyisocyanate

-

Hardeners

-

Polyisocyanurate

-

Isocyanate

-

Reactive system

Material:

Coatings, paints & inks:Fast curing, Weather resistant, Easy mixing, Waterborne

Adhesives:Moisture resistant, Fast bonding, Waterborne, Heat activated

General Characterization:

Hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).

Hardener for waterborne two-component polyurethane systems.

Logistics and Handling

Storage Conditions:

– Storage in original sealed Covestro container.

– Recommended storage temperature: 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information: Hydrophilic isocyanates are very moisture-sensitive and react with water to form carbon dioxide and insoluble ureas. The containers must always be kept tightly closed. The access of water in all forms (moist air, solvents, moist containers) must be prevented, because the generation of carbon dioxide can lead to dangerous increases in pressure. Storage at higher temperatures will result in increase of color and viscosity.

Sampling:

No data available

Technical Properties & Datasheets

Characteristics:

Property Name |

Test Method |

Unit |

Value |

Flash point |

DIN EN ISO 2719 |

°C |

approx. 192 |

Density |

DIN EN 2811 |

g/cm3 |

approx. 1.16 |

Specifications:

Property Name |

Test Method |

Unit |

Value |

Viscosity at 23 °C |

M014-ISO 3219/A.3 |

mPa*s |

3,500 ± 1,000 |

NCO content |

M105-ISO 11909 |

% |

20.3 – 21.3 |

Hazen color value |

M017-EN 1557 |

< 60 |

|

Monomeric HDI |

M106-ISO 10283 |

% |

≤ 0.24 |

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : sales@newtopchem.com

HDI Waterborne Covesro 305

HDI Waterborne Covesro 305

ABOUT:

Hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).As a hardener for aqueous two-component polyurethane systems.

Product Types:

Hydrophilic polyisocyanate

Material:

No data available

General Characterization:

Hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).

As a hardener for aqueous two-component polyurethane systems.

Logistics and Handling

Storage Conditions:

– Storage in original sealed Covestro container.

– Recommended storage temperature: 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information: Hydrophilic isocyanates are very moisture-sensitive and react with water to form carbon dioxide and insoluble ureas. The containers must always be kept tightly closed. The accessof water in all forms (moist air, solvents, moist containers) must be prevented, because the generation of carbon dioxide can lead todangerous increases in pressure. Storage at higher temperatures will result in increase of color and viscosity.

Sampling:

No data available

Technical Properties & Datasheets

Characteristics:

Property Name |

Test Method |

Unit |

Value |

Density |

DIN 53 217 |

g/cm3 |

approx. 1.16 |

Equivalent weight |

approx. 260 |

||

Flash point |

DIN EN 53 213 |

°C |

approx. 230 |

Specifications:

Property Name |

Test Method |

Unit |

Value |

Hazen color value |

DIN EN 1557 |

≤ 150 |

|

NCO content |

DIN EN ISO 11 909 |

% |

16.2 ± 0,4 |

Monomeric HDI content |

DIN EN ISO 10 283 |

% by wt. |

< 0.15 |

Viscosity at 23 °C |

DIN EN ISO 3219/A.3 |

mPa*s |

6,500 ± 1,500 |

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : sales@newtopchem.com

HDI Waterborne Covesro 304

HDI Waterborne Covesro 304

ABOUT:

Hydrophilically modified, aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI). As the hardener/binder component for high-quality waterborne polymer dispersions and as an additive to improve the property level of waterborne coating and adhesive systems.

Product Types

-

HDI

-

PIC

-

Hydrophilic polyisocyanate

-

Aliphatic polyisocyanate

-

Crosslinkers

-

Polyisocyanate

-

Hardeners

-

Polyisocyanurate

-

Isocyanate

-

Reactive system

Material:

Coatings, paints & inks:High functional, Weather resistant, Easy mixing, Ultra-low monomer, Waterborne

Adhesives:Moisture resistant, Ultra-low monomer, Waterborne, Heat activated

General Characterization:

Hydrophilically modified, aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).

As the hardener/binder component for high-quality waterborne polymer dispersions and as an additive to improve the property level of waterborne coating and adhesive systems.

With respect to its composition, the product corresponds to the following sections of the U.S. FDA’s guidelines Title 21 CFR: Section 175.105 “Adhesives”.

Storage Conditions:

– Storage in original sealed Covestro container.

– Recommended storage temperature: 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information: Hydrophilic isocyanates are very moisture-sensitive and react with water to form carbon dioxide and insoluble ureas. The containers must always be kept tightly closed. The access of water in all forms (moist air, solvents, moist containers) must be prevented, because the generation of carbon dioxide can lead to dangerous increases in pressure. Storage at higher temperatures will result in increase of color and viscosity. Due to the raw materials, the product may show visible turbidity caused by the cold. This turbidity occurs at approx. + 5 °C and is reversible when heated to room temperature. The product properties are not affected.

Sampling

No data available

Technical Properties & Datasheets

Characteristics:

Property Name |

Test Method |

Unit |

Value |

Flash point |

DIN EN 22719 |

°C |

226 |

Equivalent weight |

approx. 230 |

||

Density |

DIN 51757 |

g/ml |

approx. 1.16 |

Specifications:

Property Name |

Test Method |

Unit |

Value |

NCO content |

M105-ISO 11909 |

% |

18.2 ± 0.5 |

Color value (Hazen) |

M017-EN 1557 |

≤ 60 |

|

Viscosity at 23 °C |

M014-ISO 3219/A.3 |

mPa*s |

4,000 ± 1,500 |

Monomeric HDI |

M106-ISO 10283 |

< 0.10 |

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : sales@newtopchem.com

HDI Waterborne DIC 5500

HDI Waterborne DIC 5500

ABOUT:

The product data shown here are not sales specifications. When you import/use the product, you need to confirm whether the regulations of the country/region are applicable or not. Please refer to SDS concerning safety and handling of the product.

Description:

Water dispersible polyisocyanate hardener.

Applications:

Industrial coatings.

Protective coatings.

Wood coatings.

Hardener for 2K waterborne polyurethane coatings.

Key features:

Dispersibility in water.

Stability in water.

Compatible with main resins.

Characteristics:

Solvent |

Methoxypropyl acetate |

Solids content, % |

79.0 – 81.0 |

Viscosity, Gardner |

G – M |

Acid value on solution, mgKOH/g |

– |

OH value on solution, mgKOH/g |

13.0 – 14.0 (NCO content, %) |

EEW, g/eq |

– |

pH |

– |

Color, Gardner |

– |

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

E_mail us : sales@newtopchem.com

HDI Waterborne WanHua 278

HDI Waterborne WanHua 278

Product Description:

Aquolin 278 is a water dispersible polyisocyanate based on hexamethylene diisocyanate(HDI). In combination with waterborne polyurethane, polyacrylate, etc., it can be used for water-borne coatings. Thanks to its low viscosity and ease of handmixing, Aquolin 278 can be used to prepare “solvent-free hardener” in order to produce ultralow VOC coatings. After addition of Aquolin 278, the ready-to-use mixture must be used within the pot life.

Properties:

-

Matting effect.

-

Excellent water dispersibility.

-

Excellent weather resistance.

Characteristic data*

Property |

Value |

Unit |

Method |

Appearance |

Colorless to yellowish transparent liquid |

||

NCO content |

22.5±0.5 |

% |

GB/T 12009.4-2016 |

Viscosity |

1500-3500 |

mPa·s |

Brookfield LV, 63#/3rpm,25°C |

Color APHA |

<80 |

GB/T 1722-1992 |

|

Monomericisocyanate |

≤ 0.2 |

% |

GB/T 18446-2009 |

Flash point |

~196 |

°C |

GB/T 5208 |

Density |

~1.16 |

g/cm3 |

GB/T 4472-2011 |