HDI closed Vencorex D2

Description:

Blocked aliphatic polyisocyanate (HDI homopolymer), supplied at 75 % solids in aromatic solvent.

Specifications:

Colour

|

≤40 HAZEN (APHA)

|

Viscosity at 25°C

|

2500 – 4000 mPa.s

|

NCO (available after deblocking)

|

11.2 ±0.5 %

|

Solids content

|

75.0±2.0 %

|

Free NCO

|

< 0.2 %

|

The analytical methods are available upon request

Physical Properties:

Appearance

|

Clear liquid

|

Bulk density at 25°C

|

1060 kg/m3 approx.

|

Weight per US gallon

|

8.85 lbs approx.

|

Flash point (closed cup)

|

49°C approx.

|

Equivalent weight (on delivery form)

|

375 g approx.

|

Solubility:

Soluble in esters, ketones, aromatic hydrocarbons. In most cases, esters/aromatic hydrocarbon mixtures are used.

Applications:

Tolonate™ D2 is typically used as a crosslinker of hydroxylated polymers notably polyesters and polyacrylates to prepare heat activated one component polyurethane systems for weatherable coatings giving excellent mechanical properties in conjunction with outstanding resistance to solvents, abrasion and chemical products. Tolonate™ D2 is commonly used in Automotive OEM formulations, can and coil coatings and other general industrial coatings on metal. The curing conditions are generally 20 to 40 minutes at 140-160°C (285-305°F) or 30 to 35 seconds at 320°C (PMT = 232 / 241°C).

Packaging and transport

Packaging (please contact our sales team for more details)

-

US origin: 215 kg net metallic drum

-

France origin: deliveries of 860 kg net weight pallets (4 drums of 215 kg netweight).

-

Other packaging: upon request

Transport:

-

Regulated. For more precise details, please refer to the safety data sheet

Storage conditions and shelf-life:

-

Tolonate™ D2 is not affected by moisture at room temperatue.

-

Appropriate storage for two years does not normally affect Tolonate™ D2 in anyway if it is stored in its sealed original drums inusual storage condition, at temperatures bellow 40°C.

Flammability and safety instructions:

Before handling this product please refer to its safety data sheet

HDI closed Covesro BL 3175 SN

ABOUT:

Blocked aliphatic HDI-polyisocyanate. With Desmophen® grades to formulate lightfast one-component polyurethane stoving coatings; as an additive to improve flexibility and adhesion.

Product Types:

-

HDI

-

PIC

-

Aliphatic polyisocyanate

-

Crosslinkers

-

Polyisocyanate

-

Hardeners

-

Polyisocyanurate

-

Isocyanate

Material:

Coatings, paints & inks:

Solventborne, Flexible, Thermally resistant, Elastic

General Characterization:

Blocked, aliphatic polyisocyanate based on HDI.

In combination with Desmophen® grades to formulate lightfast, one-component polyurethane stoving coatings; as an additive in conventional stoving systems to improve flexibility and adhesion.

Storage Conditions:

– Storage in original sealed Covestro container.

– Recommended storage temperature: 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information: Storage at higher temperatures will result in increase of color and viscosity. Storage at significant lower temperatures will result in solidification. This solidification is reversible by briefly heating the product without adversely affecting the quality of the product.

Characteristics:

Property Name

|

Test Method

|

Unit

|

Value

|

Equivalent weight

|

|

|

approx. 380

|

Density at 20 °C

|

DIN EN ISO 2811

|

g/ml

|

approx. 1.06

|

Flash point

|

DIN 53 213/1

|

°C

|

approx. 45

|

Blocked NCO content

|

|

%

|

approx. 11.1

|

Viscosity at 25 °C

|

M014-ISO 3219/A.3

|

mPa*s

|

approx. 2,800

|

Specifications:

Property Name

|

Test Method

|

Unit

|

Value

|

Color value (Hazen)

|

M017-EN 1557

|

|

≤ 60

|

Viscosity at 23 °C

|

M014-ISO 3219/A.3

|

mPa*s

|

3,300 ± 400

|

Free NCO content, modified

|

M105-ISO 11909

|

%

|

≤ 0.2

|

Non-volatile content (0.2 g / 60 min / 80 °C)

|

M020-ISO 3251

|

%

|

75 ± 2

|

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

HDI closed AsahiKasei SBN-70D CAS 34590-94-8

ABOUT:

Category : Isocyanate

Industry:

Description:

DURANATE SBN-70D by Asahi Kasei is a low cruing temperature types blocked hexamethylene diisocyanate (HDI) trimer with low baking colanation, Shows lower temperature curing feature particularly in case of thin film thickness. Acts as a curing agent for urethanes. Provides excellent weatherability, good chemical & abrasion resistance, good adhesion and drying properties. Shows excellent color retention and outstanding performance. DURANATE SBN-70D is suitable for applications of automotive, adhesives and coil coating. Possible applications could be coatings for architectural, industrial, consumer electronic and information technology, gravure, offset and screen inks.

Component:

Substance Component Name

|

Content* (%)

|

CAS NO.

|

Blocked polyisocyanate

|

Approx. 70

|

included

|

dipropylene glycol monomethyl

ether

|

Approx.30

|

34590-94-8

|

*These content values only show the amount of a particular ingredient and are not strictly regulated.

Physical and chemical properties

Appearance and properties: colorless to light yellow liquid

Odor: pleasant odor

Odor threshold: not available

pH: no information

Melting/freezing point (℃): no information available

Initial boiling point and boiling range (℃): dipropylene glycol monomethyl ether 190 ℃;

Flash point (°C): 98 (Sitter closed cup type)

Evaporation rate: Dipropylene glycol monomethyl ether 0.02 (Butyl acetate = 1)

Flammability (solid, gaseous): no information available

Upper and lower flammability limits or explosion limits (Vol%): no information available

Vapor Pressure (kPa): 0.05 (25℃)

Vapor Density: Dipropylene glycol monomethyl ether 5.11 (Air=1)

Relative density (water=1): 1.13 (20℃)

Solubility: insoluble in water

n-octanol/water partition coefficient:

Dipropylene glycol monomethyl ether: log Kow = 0.006

Autoignition temperature (℃): no information

Decomposition temperature (℃): no information

Stability and reactivity:

STABILITY: Stable under normal and recommended operating, storage and disposal conditions.

HAZARDOUS REACTIONS: This product may react slowly with water to produce CO2, resulting in an increase in pressure and expansion of closed containers, creating a bursting hazard.

Hazardous Reactions: This product may react slowly with water to produce CO2, resulting in increased pressure and expansion in closed containers, creating a burst hazard.

Conditions to be avoided: Keep away from high temperatures, heat sources, sparks and flames, prevent static hazards, avoid heating closed containers, avoid temperatures close to or exceeding their flash points.

Avoid heating of closed containers and temperatures near or above their flash points.

Polymerization Hazard: No information available

Incompatible substances: water, strong bases, strong oxidizing agents.

Hazardous Decomposition Products: Carbon monoxide, oxides of nitrogen, isocyanates, traces of hydrogen cyanide can be produced upon heating.

R caution and S caution:

R36 Irritating to eyes;

S1/2 Store under lock and key and out of reach of children;

S7/9 Keep container tightly closed in a well-ventilated place;

S14 Keep away from water, strong alkalis and strong oxidizing agents;

S16 Keep away from ignition sources and prohibit smoking;

S20/21 Do not eat, drink or smoke when in use;

S24/25 Avoid skin and eye contact;

S26 Immediately after eye contact, flush with plenty of water and seek medical advice;

S27 Remove all contaminated clothing immediately;

S28 after skin contact, wash immediately with plenty of water and soap;

S36/37/39 Wear appropriate protective clothing, gloves and eye/face protection;

S45 In case of accident or if feeling unwell, seek medical attention immediately (show label if possible);

S63 In case of accidental inhalation, remove victim to fresh air and rest;

S64 in case of swallowing, rinse mouth with water (for conscious patients only).

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

HDI Quick drying AsahiKasei MHG-80B

HDI Quick drying AsahiKasei MHG-80B

ABOUT:

DURANATE™ MHG-80B by Asahi Kasei is a hard, highly crosslinkable hexamethylene diisocyanate (HDI). Acts as a curing agent for urethanes. Exhibits excellent weatherability, good chemical & abrasion resistance, good adhesion and drying properties. Shows excellent color retention and outstanding performance. Possible applications could be coatings for automotive, architectural, industrial, consumer electronic and information technology. Other applications of DURANATE™ MHG-80B may include gravure, offset and screen inks.

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

HDI trimer show respect DH-100

ABOUT:

Product Class: Isocyanate

DURANATE TKA-100 by Asahi Kasei is a hexamethylene diisocyanate (HDI) trimer. Acts as a curing agent for urethanes. Exhibits excellent color retention,weatherability and outstanding performance. Possible applications could be coatings for automotive, architectural, industrial, consumer electronic and information technology. Other applications of DURANATE TKA-100 may include gravure, offset and screen inks. Shows superior weatherability, good chemical & abrasion resistance, good compatibility and drying properties.

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

HDI trimer HDT-100

ABOUT:

Tolonate™ HDT is a medium viscosity, solvent-free aliphatic polyisocyanate, used to produce 2K polyurethane coatings with superior performances.

BENEFITS:

-

Abrasion Resistance,

-

Hardness,

-

Weathering Resistance

APPLICATIONS:

-

Coatings & Adhesives,

-

Adhesives & Sealants,

-

Automotive OEM & refinish,

-

General Industry,

-

Transportation

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

HDI trimer HX-100

ABOUT

CHEMICAL CHARACTERIZATION:

HDI based modified polyisocyanate, containing isocyanurate

FORM:

Non-solvent, 100% of solid content.

USES:

Hardener for two-component, non-yellowing type of polyurethane paint with excellentweathering ability.

CHARACTERISTICS:

|

|

Coronate-HX

|

appearance

|

Pale yellow liquid

|

NCO content (%)

|

20.5-22.0

|

Solid content (%)

|

100

|

Viscosity 25°C (Gardner No.)(mPa.s)

|

X – Z21,290 – 3,620

|

Color (Gardner No.)

|

≤1

|

Monomer HDI(%)

|

≤0.4

|

FEATURES:

CORONATE HX is a hardener for non-yellowing type of PU paints, with superiorperformance to conventional biuret or adduct types of hardeners. CORONATE HX iswidely accepted in the paint industry for various applications, such as motor bike parts,automotive parts, automotive finishing, wood finishes, etc. This is because of itsresistance to high heat, high solubility in solvents and good compatibility with polyols.

APPLICATIONS:

The combination of CORONATE HX with acrylic polyols produces non-yellowingtype of’ paint with excellent weathering ability and resistance against ultra-violet rays.by which its original color could be long sustained. This two-component type ofpaint is applied for automotive refinishes, industrial purposes, etc.

The combination of CORONATE HX with alkyd polyols results in two-componenttype of paint, which is applied for industrial purpose, wood finishes, etc.

The addition of CORONATE HX to some nitro-cellulose based or polyurethane basedpaints distinctively improves their physical properties, such as chemical resistance tosolvents. However, it is necessary to test the compatibility for each combination andgreat care should be taken during testing.

HANDLING INSTRUCTIONS

STORAGE CONDITIONS:

CORONATE HX should always be kept in a closed container at room temperaturefor long period of storage. This is to prevent any contact with moisture in the air.since this product is a chemical compound and is highly active with hydroxyl groups.This product should be stored indoors at room temperature (15-25°C).

AT THE TIME OF USE / RE-PACKING:

The reaction of water with the NCO groups in this product causes not only theformation of insoluble products such as urea groups, but also CO, gas, whichincreases the pressure in a closed container, thus resulting in an expansion of thecontainer.Ihe operation for partial use of this product or emptying of a drum should becarriedout with great care in order to prevent any contamination with moisture.The operation to transfer this product into another container should be done under adry atmosphere, then sealed with dry nitrogen before sealing.

DILUTION WITH SOLVENTS:

When this product has to be diluted with solvents, the water content of the solventshould be as low as possible, and great care should be taken during dilution in orderto prevent contamination with water. In addition, this operation should be carriedout under a dry atmosphere.In case of this product needs to be diluted with the desired solvent, the DilutionStability Test of the final formulation under the application conditions is stronglyrecommended.There is a possibility of precipitation, generation of gel-type substance or haze, if thedilution formulation was inappropriate.

Please note that all the dilution work is under customer’s responsibility

SAFETY PRECAUTIONS:

-

Care must be taken when handling CORONATE HX as it contains active isocyanateand solvent.

-

Please refer to MSDS concerning its hazards, proper use, and handling before workingwith this product.T

-

his product is flammable. Therefore, the use of fire is prohibited in the work area.

-

Appropriate safety measures and protective equipment such as goggles and gloves.should be used when working with this product in order to prevent contact with skin.

-

CORONATE HX is mainly applied for spray coatings. A protective mask should beworn in order to prevent inhalation of spraying mist.

-

CORONATE HX contains below 0.4% of free isocyanate. This value does notincrease even if this product is stored over a long period.

STANDARD PACKING:

CORONATE HX

|

220 kgs ( 200L iron drum )

|

|

20 kgs( 18L tin can)

|

HDI Low viscosity TPA-100

Type :

Aliphatic Polyisocyanate (HDI Trimer)

Features:

# High NCO content

# Lower viscosity

# Good coated film appearance

# Good weather resistance

# Low residual monomer

Applications:

# Two-component applications# Plastic coatings# Auto refinish coatings

# Automobile, motorcycle ; base coat and top coat# Heavy duty coatings

Typical properties:

Appearance

|

Colorless to slightly yellowish clear liquid

|

Non-volatile

|

100 wt%

|

Solvent

|

NONE

|

NCO content

|

23.1 wt%

|

Viscosity

|

1400 mPa .s at 25°C

|

Color value

|

<1 (Gardner)

|

NCO equivalent weight

|

Approx.182

|

Flash point

|

252°C

|

Density at 20°c

|

1.17

|

These values provide general information and are not part of the productspecifications.

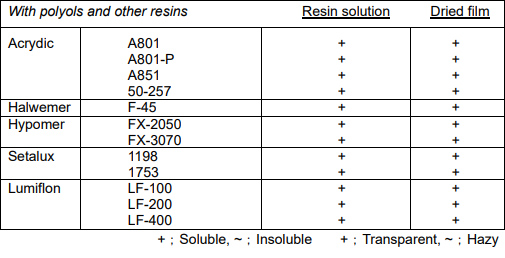

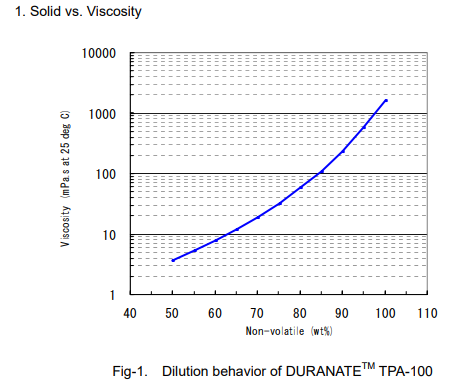

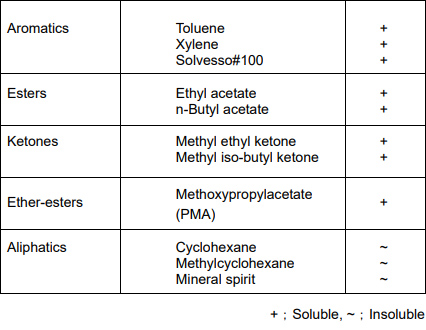

Stability / thinnability:

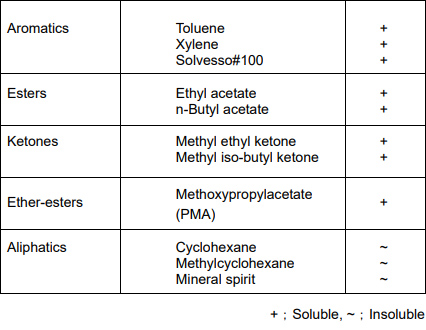

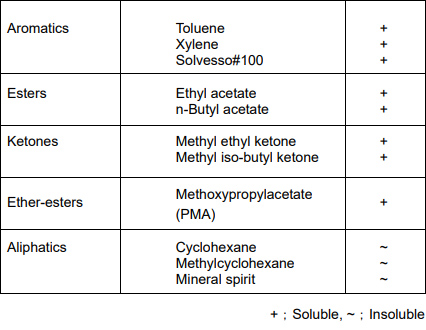

DURANATETM TPA-100 can be thinned with esters,

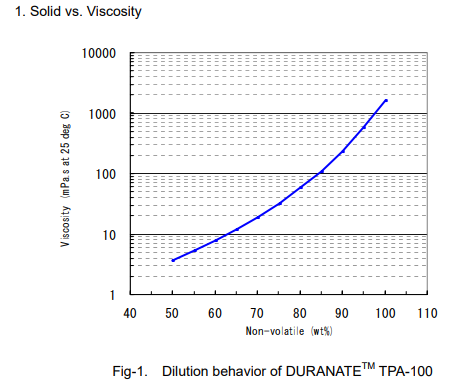

ketones and aromatichydrocarbons such as ethyl acetate, butyl acetate, methoxypropylacetate(PMA), methylethyl ketone, methyl-butyl ketone, cyclohexanone,toluene, xylene, Solvesso #100 andmixture thereof. Generally speaking, it has good compatibility with thesolventmentioned. However, the solutions formed must be tested for their storage stability.Only PU grade solvents can be used (max. 0.05% water, absence of reactive groupssuch as hydroxyl or amines groups). Aliphatic hydrocarbons such as hexane.cyclohexane, methylcyclohexanes and mineral spirits, are unsuitable as solventsbecause of their poor solubility.

DURANATETM TPA-100 should not be thinned to below a solid content of 40%.Prolonged storage of solution with lower solid content may result in turbidity andsedimentation.

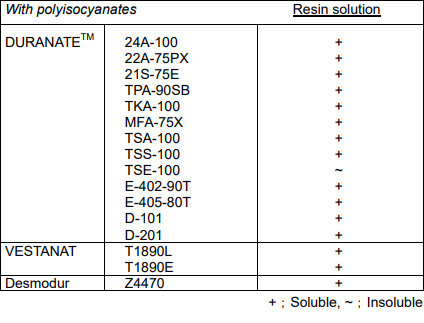

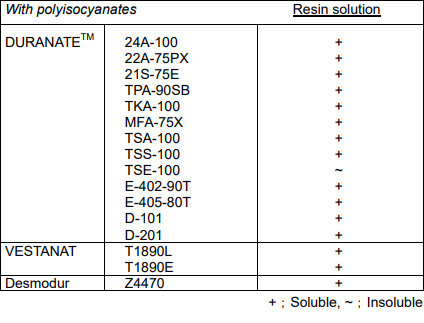

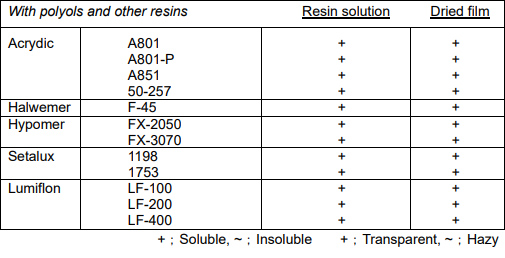

Compatibility:

Mixing ratio of DURANATETM TPA-100 with polyols is based on NCO/OH equivalentratio of 1/1.

Storage:

DURANATETM TPA-100 is sensitive to moisture and should therefore always be storedin sealed containers.

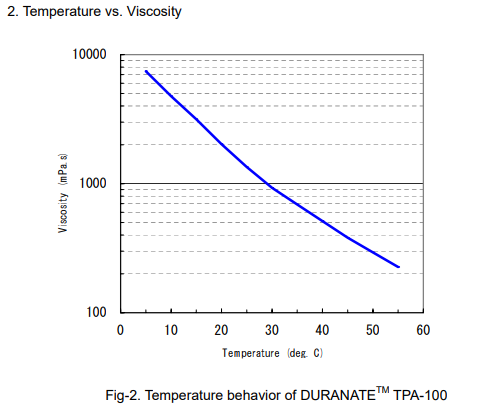

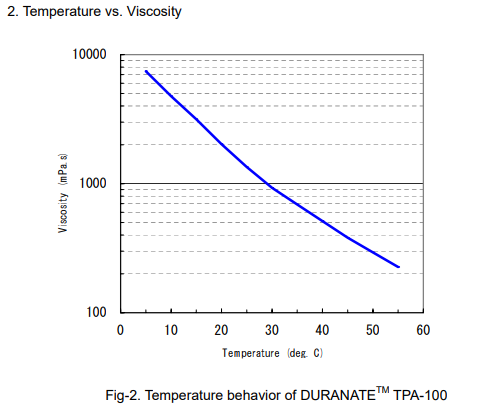

Characteristics of iscosity:

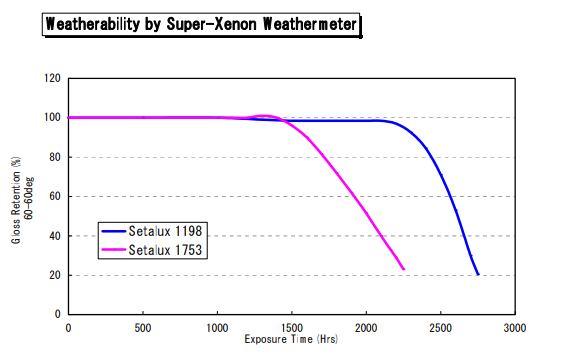

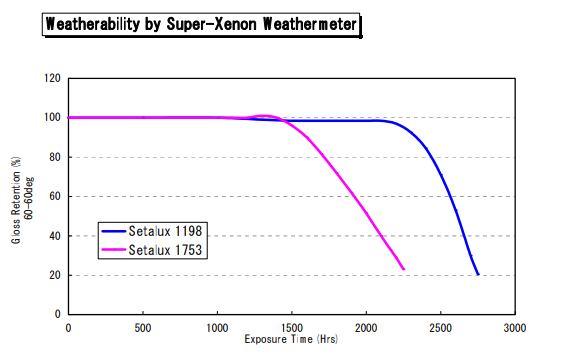

Weatherability:

Fig-3. Weatherability of DURANATETM TPA-100 with acrylic polyol

Polyol; Setalux 1198 & 1753 (Nuplex Resins)Weathered by Super-Xenon Weathermeter

HDI Waterborne AsahiKasei WE50-100

HDI Waterborne AsahiKasei WE50-100

ABOUT:

DURANATE™ WE50-100 by Asahi Kasei is a water dispersible hexamethylene diisocyanate (HDI). Acts as a curing agent for urethanes. Exhibits excellent color retention and outstanding performance. Provides good elasticity, excellent good chemical & abrasion resistance, good adhesion and drying properties. Possible applications could be coatings for automotive, architectural, industrial, consumer electronic and information technology. Other applications of DURANATE™ WE50-100 may include gravure, offset and screen inks.

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

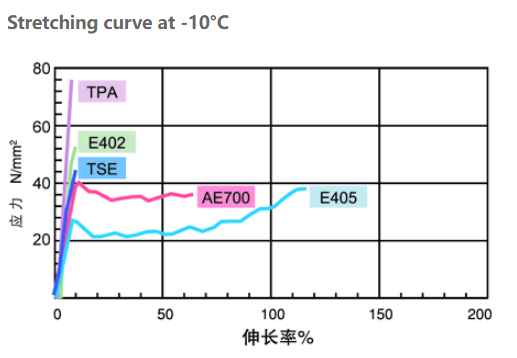

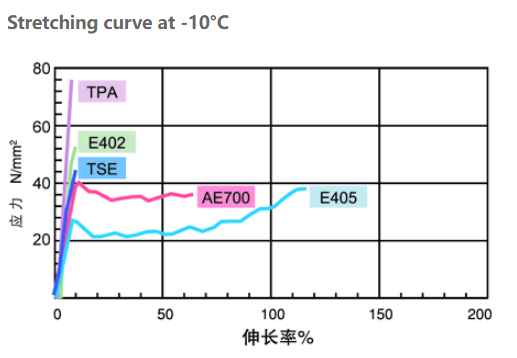

HDI Elastic type Covesro E402-90T E405-80T TSE-100

Product introduction:

Coating films with elasticity and excellent weather resistance can be obtained without adding plasticizers.

It is suitable for elastic substrates such as plastic, leather, rubber and other materials that require tensile properties.

DonadTM

model

|

solid content

wt%

|

NCO%

wt%

|

Viscosity

mPa·s/25°C

|

solvent

|

Features

|

E402-90T

|

90

|

8.5

|

1200

|

Toluene

|

elasticity

|

E405-80T

|

80

|

7.1

|

230

|

Toluene

|

low temperature elasticity

|

TSE-100

|

100

|

12.0

|

1650

|

—

|

Soluble in low polar solvents

|

AE700-100

|

100

|

11.9

|

800

|

—

|

low temperature elasticity

Soluble in low polar solvents

|

* Please inquire about changing the dilution solvent

BDMAEE Manufacture !