HDI Elastic type Covesro N3800

ABOUT:

Aliphatic polyisocyanate (flexibilizing HDI trimer).As the hardener component for lightfast polyurethane coating systems.

Product Types:

-

HDI

-

PIC

-

Aliphatic polyisocyanate

-

Crosslinkers

-

Polyisocyanate

-

Hardeners

-

Polyisocyanurate

-

Isocyanate

Material:

Coatings, paints & inks:High functional, Weather resistant, Solventborne, Flexible, Elastic

Technical Properties & Datasheets

Characteristics:

Property Name

|

Test Method

|

Unit

|

Value

|

Viscosity at 23 °C

|

M014-ISO 3219/A.3

|

mPa*s

|

6,000 ± 1,200

|

NCO content

|

M105-ISO 11909

|

%

|

11.0 ± 0.5

|

Color value (Hazen)

|

M017-EN 1557

|

|

≤ 80

|

Monomeric HDI

|

M106-ISO 10283

|

%

|

≤ 0.25

|

Specifications:

Property Name

|

Test Method

|

Unit

|

Value

|

Flash point

|

DIN 22 719

|

°C

|

approx. 235

|

Equivalent weight

|

|

|

approx. 382

|

Viscosity at 25 °C

|

DIN EN ISO 3219/A.3

|

mPa*s

|

approx. 5,500

|

Density at 20 °C

|

DIN EN ISO 2811

|

g/ml

|

approx. 1.12

|

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

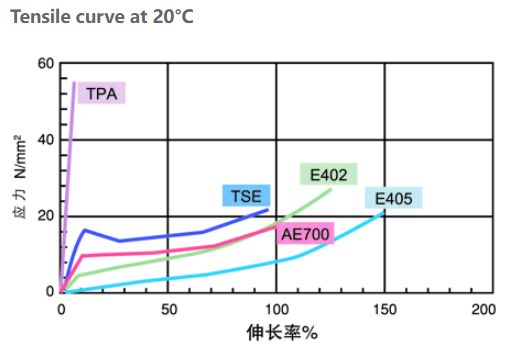

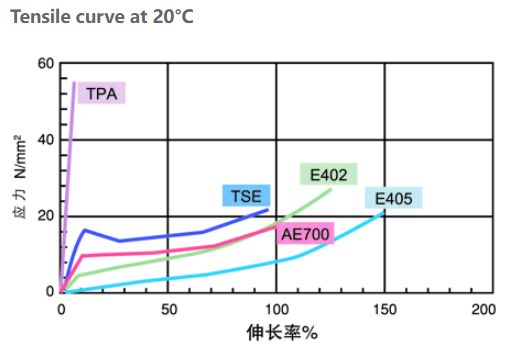

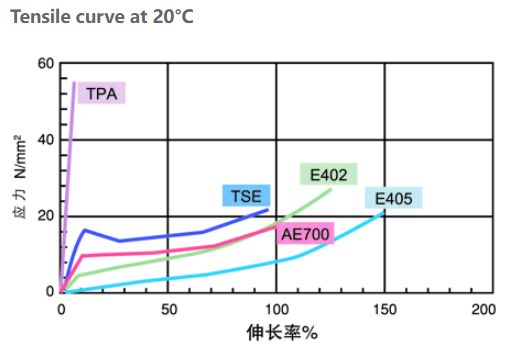

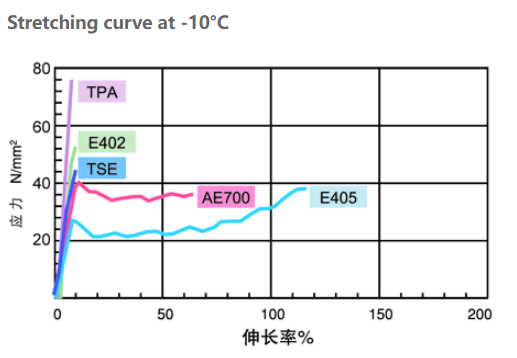

HDI Elastic type Covesro E402-90T E405-80T TSE-100

Product introduction:

Coating films with elasticity and excellent weather resistance can be obtained without adding plasticizers.

It is suitable for elastic substrates such as plastic, leather, rubber and other materials that require tensile properties.

DonadTM

model

|

solid content

wt%

|

NCO%

wt%

|

Viscosity

mPa·s/25°C

|

solvent

|

Features

|

E402-90T

|

90

|

8.5

|

1200

|

Toluene

|

elasticity

|

E405-80T

|

80

|

7.1

|

230

|

Toluene

|

low temperature elasticity

|

TSE-100

|

100

|

12.0

|

1650

|

—

|

Soluble in low polar solvents

|

AE700-100

|

100

|

11.9

|

800

|

—

|

low temperature elasticity

Soluble in low polar solvents

|

* Please inquire about changing the dilution solvent

IPDI Quick drying Evonik T1890E

IPDI Quick drying Evonik T1890E

ABOUT:

VESTANAT® T 1890 is a cycloaliphatic polyisocyanate crosslinker with remarkably short curing cycles even at ambient temperatures.

POLYISOCYANATE CROSSLINKERS IN 2K SYSTEMS:

-

Combination with a resin component right before application

-

Reaction starts immediately after mixing the polyisocyanate with the resin component

-

Reaction leads to a 3D network with a high durability

Benefits:

-

Low viscosity

-

Excellent compatibility & high reactivity

-

Durability against environmental impacts

-

UV resistant, lightfast and very good gloss retention

-

First-class chemical resistance

-

High reactivity even at ambient temperature

-

Short curing cycles

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

IPDI Quick drying Covesro Z4470 SN

ABOUT:

Aliphatic polyisocyanate (IPDI trimer).As the hardener component for lightfast polyurethane coating systems and as an additive resin for alkyd spray coatings.

Product Types:

-

PIC

-

IPDI

-

Aliphatic polyisocyanate

-

Crosslinkers

-

Polyisocyanate

-

Hardeners

-

Polyisocyanurate

Material:

Coatings, paints & inks:Fast curing, Weather resistant, Solventborne, Hard

General Characterization:

Aliphatic polyisocyanate (IPDI trimer).

As the hardener component for lightfast polyurethane coating systems and as an additive resin for alkyd spray coatings.

Storage Conditions:

– Storage in original sealed Covestro container.

– Recommended storage temperature: 0 – 30 °C.

– Protect from moisture, heat and foreign material.

General information: The product is sensitive to moisture. Storage at higher temperatures will result in increase of color and viscosity. Storage at significant lower temperatures will result in solidification. This solidification is reversible by briefly heating the product without adversely affecting the quality of the product.

Technical Properties & Datasheets

Characteristics:

Property Name

|

Test Method

|

Unit

|

Value

|

Density at 20 °C

|

DIN EN ISO 2811

|

g/ml

|

approx. 1.05

|

Equivalent weight

|

|

|

approx. 360

|

Flash point

|

DIN 53 213/1

|

°C

|

approx. 45

|

Viscosity at 25 °C

|

M014-ISO 3219/A.3

|

mPa*s

|

approx. 1700

|

Specifications:

Property Name

|

Test Method

|

Unit

|

Value

|

Viscosity at 23 °C

|

M014-ISO 3219/A.3

|

mPa*s

|

2,000 ± 600

|

Non-volatile content (0.2 g/1 h/120 °C)

|

M020-ISO 3251

|

%

|

70 ± 2

|

NCO content

|

M105-ISO 11909

|

%

|

11.9 ± 0.4

|

Monomeric IPDI

|

M106-ISO 10283

|

%

|

< 0.35

|

Color value (Hazen)

|

M017-EN 1557

|

|

≤ 60

|

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

HDI Waterborne WanHua 160

Product Description:

Aquolin 161 is a water dispersible polyisocyanate based on hexamethylene diisocyanate (HDI). In combination with water-borne polyurethane, polyacrylate, etc., it can be used for adhesive products toimprove the resistance to hydrolysis and heat. It also can be used for waterborne coatings. After addition of Aquolin 161, the ready-to-use mixture must be used within the pot life.

Aquolin 161 can be diluted with the solvents, such as propylene glycol methyl ether acetate (PMA), propylene glycol diacetate (PGDA), butyl acetate, etc. Only PU grade solvents (< 0.05% water) should be used and the solvents must be tested in advance by the user to determine suitability.

Product Features:

-

Excellent resistance

-

Long pot life

-

Good gloss and building up

Characteristic Data* :

Property

|

Value

|

Unit

|

Method

|

Appearance

|

Transparent to

light yellow liquid

|

|

|

NCO content

|

18.2-19.2

|

%

|

GB 12009.4-2016

|

Viscosity (25°C)

|

1500-3500

|

mPa·s

|

GB/T 2794-2013

(Brookfield LV,63#/12rpm)

|

Color APHA

|

<60

|

|

GB/T 1722-1992

|

Monomeric

isocyanate

|

≤0.1

|

%

|

GB/T 18446-2009

|

Flash point

|

~226

|

%

|

GB/T 5208-2008

|

Density

|

~1.16

|

g/cm3

|

GB/T 4472-2011

|

*Property values represent typical results only and are not to be considered as specifications,subject to specific COA

Storage:

The product should be stored in dry conditions above 5°C and below 35°C with the integrity of the packaging, and prevent direct sunlight. The validity of this product is for 12 months, performance assessment is recommended before use after shelf life. The product should be protected from freezing during storage. Water dispersible polyisocyanates are very moisture-sensitive and react with water to form carbon dioxide and insoluble ureas. The generation of carbon dioxide can lead to dangerous increase s in pressure. The containers must always be kept tightly closed and the access of water in all forms must be prevented. It is suggested to use up once the package is open.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

HDI Waterborne AsahiKasei WT80-70P

ABOUT:

For high-performance coatings and water-based resins crosslinking.

Grade

|

Solids

(wt%)

|

NCO

(wt%)

|

Viscosity

(mPa・s, 25°C)

|

Solvents

contained

|

Special

properties

|

WT31-100

|

100

|

17.4

|

2,500

|

—

|

Excellent weatherability

|

WL72-100

|

100

|

21.2

|

510

|

—

|

Excellent weatherability

High NCO content

High dispersibility

|

WB40-100

|

100

|

16.6

|

4,500

|

—

|

Adhesion

|

WB40-80D

|

80

|

13.4

|

350

|

DEDG*

|

Hydrophilic-solvent dilution

High dispersibility

|

WR80-70P

|

70

|

9.2

|

390

|

PMA

|

Long pot-life

Hardness

|

WE50-100

|

100

|

11.3

|

3,000

|

—

|

Elasticity

|

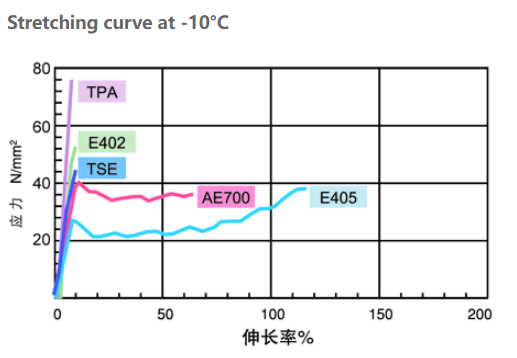

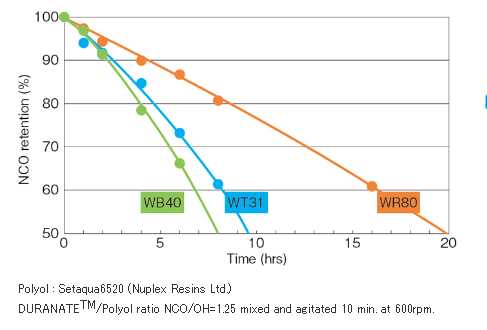

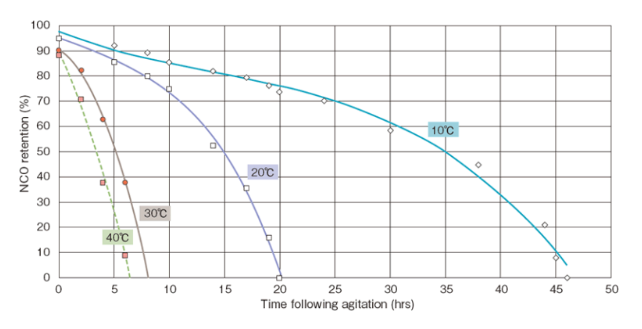

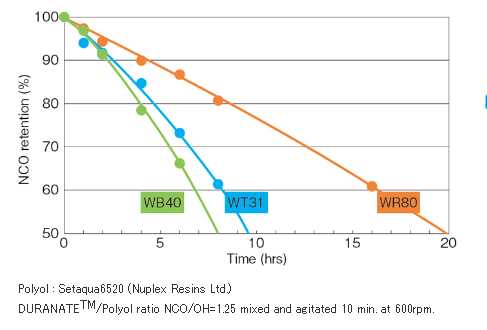

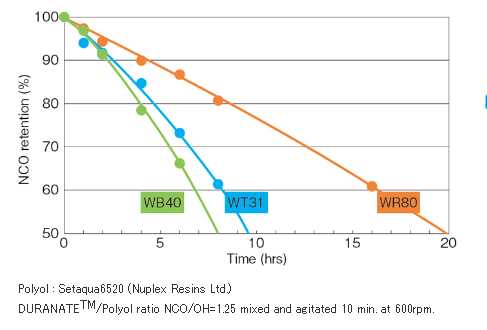

NCO retention (23℃) in mixed with polyol

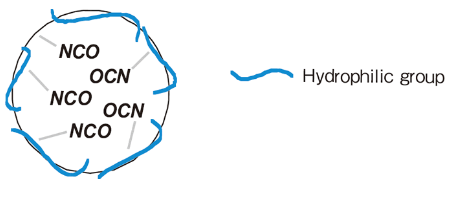

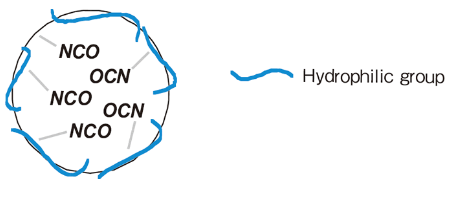

Schematic of water-dispersed configuration

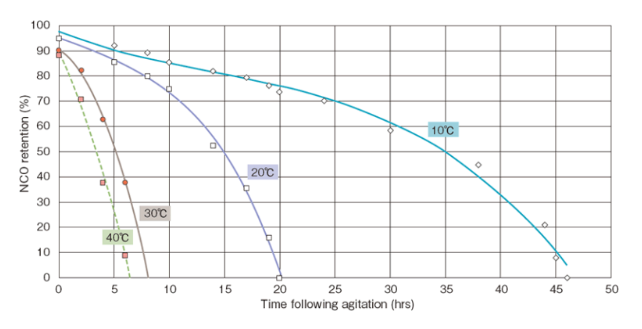

WB40-100 NCO retention (%) in water dispersion:

Test method: WB40-100/water ratio of 10/90 (NV=10%) mixed and agitated 10 min. at 600rpm;

NCO content of WB40-100 measured after agitation and at indicated time (t) thereafter.

NCO retention (%)=[(NCO% at time t)/(NCO% after agitation)]×100.

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

HDI Waterborne AsahiKasei WT36-72PB

ABOUT:

DURANATE™ WT30-100 by Asahi Kasei is a water dispersible hexamethylene diisocyanate (HDI) with urethane resin compatibility. Acts as a curing agent. Exhibits excellent color retention and outstanding performance. Offers high weatherability, excellent good chemical & abrasion resistance, good adhesion and drying properties. Applications include coatings for automotive, architectural, industrial, consumer electronic and information technology. Other applications of DURANATE™ WT30-100 may include gravure, offset and screen inks.

NCO%:116

Viscosity:300

Solid content:72%

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

HDI Waterborne AsahiKasei WL39-100

Type:

Water dispersible polyisocyanate based on hexamethylene diisocyanate

NCO%:21.4

Viscosity:1100

Solid content:100%

Features:

# High NCO content

#Low viscosity

# Long pot life

Applications:

# Automotive OEM coatings

# Automotive refinishes

#Industrial coatings(ACE, Train etc)

# Plastic coatings

# Floor coatings

#Roof coatings

Typical properties:

Appearance

|

Colorless to slightly yellowish clear liquid

|

Non-volatile

|

100 wt%

|

Solvent

|

None

|

NCO content

|

21.2 wt%

|

Viscosity

|

510 mPa .s at 25C

|

Color value

|

<1 (Gardner)

|

NCO equivalent weight

|

Approx.198

|

Flash point

|

194°C

|

Relative density

|

1.15(20°C)(H20 =1)

|

These values provide general information and are not part of the productspecifications.

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

HDI Waterborne AsahiKasei WT33-100

ABOUT:

DURANATE™ WT30-100 by Asahi Kasei is a water dispersible hexamethylene diisocyanate (HDI) with urethane resin compatibility. Acts as a curing agent. Exhibits excellent color retention and outstanding performance. Offers high weatherability, excellent good chemical & abrasion resistance, good adhesion and drying properties. Applications include coatings for automotive, architectural, industrial, consumer electronic and information technology. Other applications of DURANATE™ WT30-100 may include gravure, offset and screen inks.

NCO%:18.6

Viscosity:1600

Solid content:100%

Storage and Transportation:

STORAGE: It is recommended to store in a dry and cool area with proper ventilation.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.

BDMAEE Manufacture !