catalyst C-225

Overview:

Chinese name: Polyurethane Delayed Catalyst C-225

Alias: foaming retarder C-225, foaming retarder, high rebound retardation catalyst, high rebound retardation catalyst, C-225, catalyst C-225, polyurethane retardation catalyst C-225, retardation catalyst C-225, high Rebound Delayed Catalyst C-225, High Rebound Catalyst C-225, Soft Foam Catalyst, High Rebound Catalyst, Delayed Amine C-225, Delayed Amine Catalyst C-225, Delayed Amine Catalyst

Polyurethane delayed catalyst C-225 is used for rapid demoulding high resilience polyurethane foam amine catalyst. This catalyst can achieve a balance between the foam formation reaction and the aging reaction, optimize the fluidity of the reaction mixture, and at the same time shorten the demolding time. The formation reaction and the thermalization reaction are balanced, the fluidity of the reaction mixture is optimized, and at the same time the demolding time is shortened. Therefore, catalyst C-225 is an auxiliary agent used in the turntable production line.

Chinese name Polyurethane delayed catalyst C-225

Alias Delay catalyst C-225, catalyst C-225, C-225

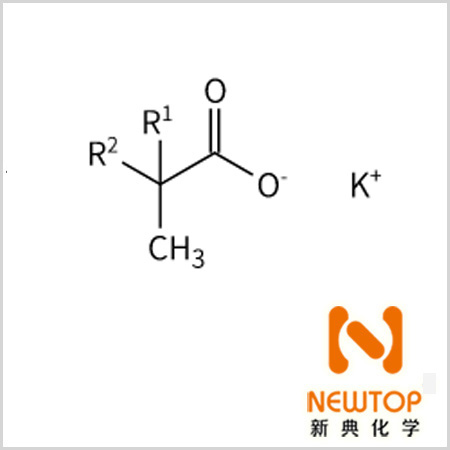

Substantial catalyst

Effect Foam formation reaction and aging reaction are balanced

Use Shorten demoulding time and increase production capacity

effect:

NT CATC-225 is an amine catalyst used for rapid demoulding of high resilience polyurethane foam, which can balance the foam formation reaction and the thermalization reaction, optimize the fluidity of the reaction mixture, and at the same time shorten the demolding time, so NT CATC-225 is an additive used in the production line of turntable car seats.

NT CATC-225 is mainly suitable for molding high resilience etc.

use:

- Shorten demoulding time and increase production capacity.

- Delayed blow-off and cross-linking balanced catalyst to optimize fluidity.

- Especially suitable for rapid cycle turntable production line.

- At the same time, it is effectively used in TDI and TDI/MDI mixed systems.

- Provide good physical properties of finished foam.

Storage and transportation:

It should be sealed and stored in a dry, cool and ventilated warehouse.

package:

200KG/drum Storage: It is recommended to store in a dry and cool area with proper ventilation. After the original packaging, please fasten the packaging cover as soon as possible to prevent the water and other substances from mixing into the product and affecting its performance. Do not breathe dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothing separately and wash it before reuse. Maintain good hygiene habits.